|

제품소개

> 광학블랙코팅

|

광학블랙코팅 광학블랙코팅 |

|

광학블랙코팅

Acktar는 높은 방사율 코팅에서 세계 리더적 역할을 하고 있습니다.

광학, 전자 및 우주응용용에 매우 높은 흡수율을 겸비한 흑색피막도포는 지금 이용가능합니다.

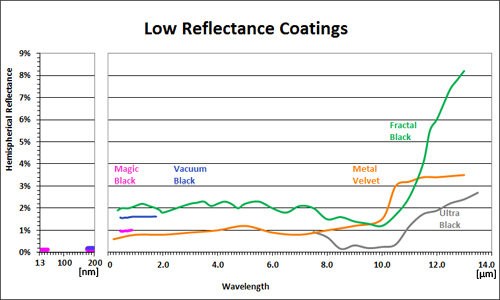

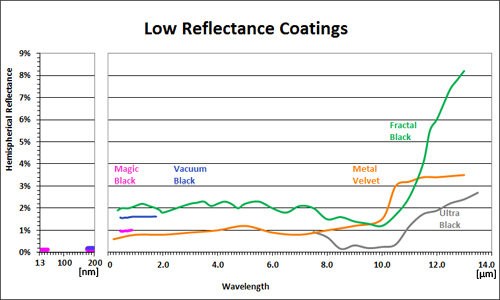

매우 낮은 반사율, 높은 열 안정성, 뛰어난 부착 및 Low outgassing 의 콤비네이션은, Acktar만의 유일무이한 특징입니다.

코팅종류

| |

나노블랙TM |

Magic BlackTM |

진공블랙TM |

프랙탈블랙TM |

울트라블랙*TM |

| Coating thickness (μm) |

0.3 - 1 |

4 - 7 |

3 - 5 |

5 - 14 |

13 - 25 |

| Working temperature |

-70 °C to +250 °C |

-269 °C to +350 °C (4°K to 623 °K) |

| Weight of coating(mg/m2) |

0.1 - 0.25 |

1.1 - 1.6 |

0.7 - 1.1 |

1.6 - 3.2 |

3.3 - 6.5 |

| Abrasion resistance |

moderate |

light |

moderate |

moderate |

moderate |

| Adhesion |

Coated pieces withstand scotch tape test (3M853 Crystal Clear tape, strength of 13N per 25mm), without any evidence of coating removal. |

| Outgassing: |

| 1. CVCM (%) |

0.001 |

| 2. RML (%) |

0.2 |

| Chemical content |

completely inorganic |

| Surface resistivity |

≤2X106Ω/□ |

| LIDT |

Laser induced damage thresholds data |

| Cleanability |

Coated pieces withstand cleaning with ethanol, IPA or acetone with no change in optical and technical characteristics.

Magic BlackTM, Metal VelvetTM and Litho BlackTM should be cleaned very gently.

|

* Ultra Black can be provided on planar parts only

** Metal Velvet can be provided only as roll/ sheet material

광학블랙코팅 - Comparison

모든 Acktar사의 코팅은 금속 벨벳 코팅TM 을 제외하고, 롤 재료로 제공 될수 있습니다. 개별 구성 요소와 롤 재료에 직접 적용 할 수 있습니다.

Data Sheet presenting all 7 coating types

|

Quick Quote - Parts Coating

|

광학블랙코팅

광학블랙코팅